-Dehumidifying Technology

Ar-Dehumidifying Technology is a truly pioneering achievement for mechanical wristwatches by our engineers – and a decisive advancement for all aficionados of mechanical watches. A three-year warranty is offered on all watches featuring Ar-Dehumidifying Technology.

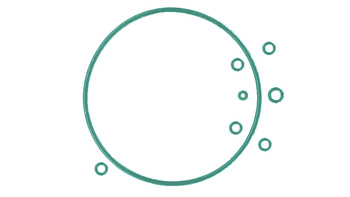

Indication colors of the drying capsule

Pale blue

Condition upon delivery

Ar-Dehumidifying Technology

Functional reliability and freedom from fogging

Ar-Dehumidifying Technology solves a basic problem of mechanical watches: the aging of oils due to moisture in the air contained inside, or diffusing into, the watch. The movement is mounted in a nearly anhydrous atmosphere thanks to the three Ar-Dehumidifying Technology elements of drying capsule, EDR seals and protective gas filling. Aging processes and fogging of the crystal from sudden cold are prevented, and reliable functioning and accuracy are ensured.

Why does a water-resistant watch need dehumidifying technology anyway?

The beauty and fascination of owning a SINN watch are enhanced by the knowledge of the fine mechanical precision of this object of daily use. Nonetheless, no matter how accurately the individual components are made, friction and wear must be minimized so that they function durably. Thus high-quality synthetic oils are used to ensure optimal lubrication of the movement bearings. This remains an unavoidable process in all mechanical watches. Humidity, however, accelerates the aging of the oils. How does moisture get into the watch? Water is always present in the atmosphere in gaseous form, which is why it can penetrate the seal systems of a watch case. Temperature changes then cause microcondensation, permitting water to collect in liquid form on exposed parts of the movement. The consequences: The efficiency of the lubrication deteriorates. Electrochemical corrosion, wear and friction increase, reducing the amplitude of the balance. The watch runs with decreasing accuracy and must finally be reconditioned. Our engineers looked for solutions to this problem and found them in the form of Ar-Dehumidifying Technology.

Mounted in a nearly anhydrous environment

These painstaking and technically elaborate measures are intended to keep the movement in a protective environment which is almost completely dry (anhydrous). A positive consequence of this is that it slows the aging process of the oil, thereby extending the functional life of the movement. Also, fogging of the crystal due to sudden temperature shocks (such as immersion in cold water) can be prevented, ensuring that the watch remains clearly legible at all times.

Three technical elements

The Ar-Dehumidifying Technology is based on three technical elements: a drying capsule, EDR seals and a protective gas filling.

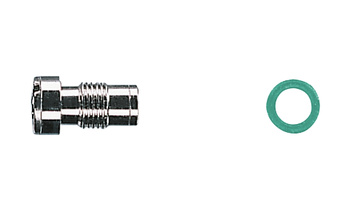

1. The drying capsule

The drying capsule is the most important part of the Ar-Dehumidifying Technology. The capsule is filled with copper sulfate; this absorbs moisture from the air inside the case and binds it permanently. Copper sulfate turns increasingly blue as its water content rises; the shade serves as an indicator of the drying capsule's level of saturation (see diagram). The capsule features a small viewing window of sapphire crystal glass for this purpose.

2. EDR seals

To minimize the exchange of gas between atmospheric air and that inside the case, and thus the penetration of atmospheric moisture, we only use Extreme Diffusion-Reducing (EDR) seals in watches featuring Ar-Dehumidifying Technology. These seals reduce the infiltration of moisture in the case to as little as 25% of the value permitted by conventional case seals made of nitrile rubber (NBR).

3. Superior protective gas filling

The Ar-Dehumidifying Technology is completed by a superior protective gas filling. This creates an ideal climate for the Ar-Dehumidifying Technology to function in. Only moisture diffusing from the air now has to be bound in the drying capsule. This avoids the humidity which is otherwise locked in during conventional assembly.